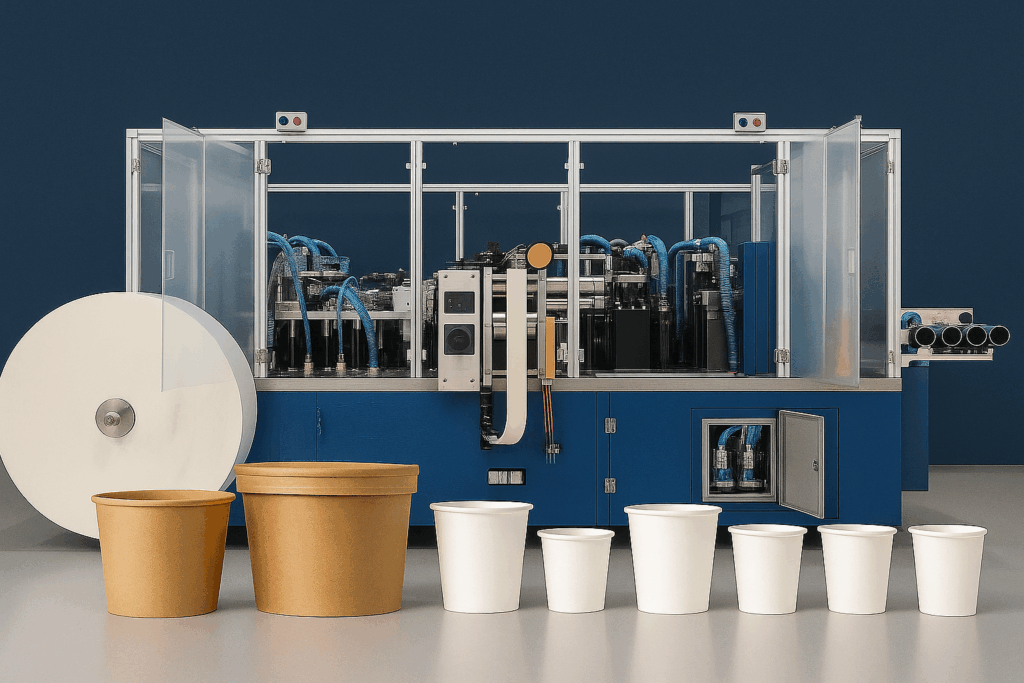

High speed paper cup machine

WSGP1700

HIGH SPEED PAPER CUP FORMING MACHINE

Key Features and Specifications of Our High Speed Paper Cup Machine

Highly Durable Power Transmission System

Our high speed paper cup machine is engineered with a robust transmission system designed for long-lasting mechanical performance. Even during continuous, high-speed operation, the system shows minimal wear, ensuring reliability over years of use.

Consistent Production Speed Over Time

This WSGP-1700 maintains stable and consistent output, even during extended production runs. It delivers the same performance from the first cup to the last, helping you meet demanding production schedules without fluctuation

Integrated Real-Time Quality Inspection System

In our high speed paper cup machine, the integrated inspection module continuously monitors cup forming, sealing, and cutting processes. Defects such as improper sealing, misalignment, or shape deformation are detected instantly, ensuring only high-quality cups are produced without slowing down production.

Very Low or nearly no Vibration Operation

Our WSGP 1700 is built with precision engineering for smooth, low-vibration operation. Even at maximum speed, the machine remains stable and quiet, improving workplace comfort and extending machine life.High Production Capacity

The high speed paper cup machine achieves 180–200 cups per minute, even for cup sizes up to 16oz. This high capacity ensures faster order fulfillment and improved productivity.Automatic Lubrication System

For minimal maintenance and maximum uptime, our WSGP-1700 features an automatic lubrication system, ensuring all critical components run optimally

Side Sealing

Preheating: Hot air

Main Sealing: Long time press by rotation mold

Bottom Sealing

Sealed by hot air

Compatible Paper Coatings

ONLY PE

Compatible Paper Types

Single-side and double-side coated paper

Production Speed

180-200 cups/min (based on 16oz cups)

Speed adjustable via inverter

Control System

PLC controller for high precision and stable operation

Electric Power Requirement

Start-up power: 35kW

Features

Explore Video Playlist

Video Collection