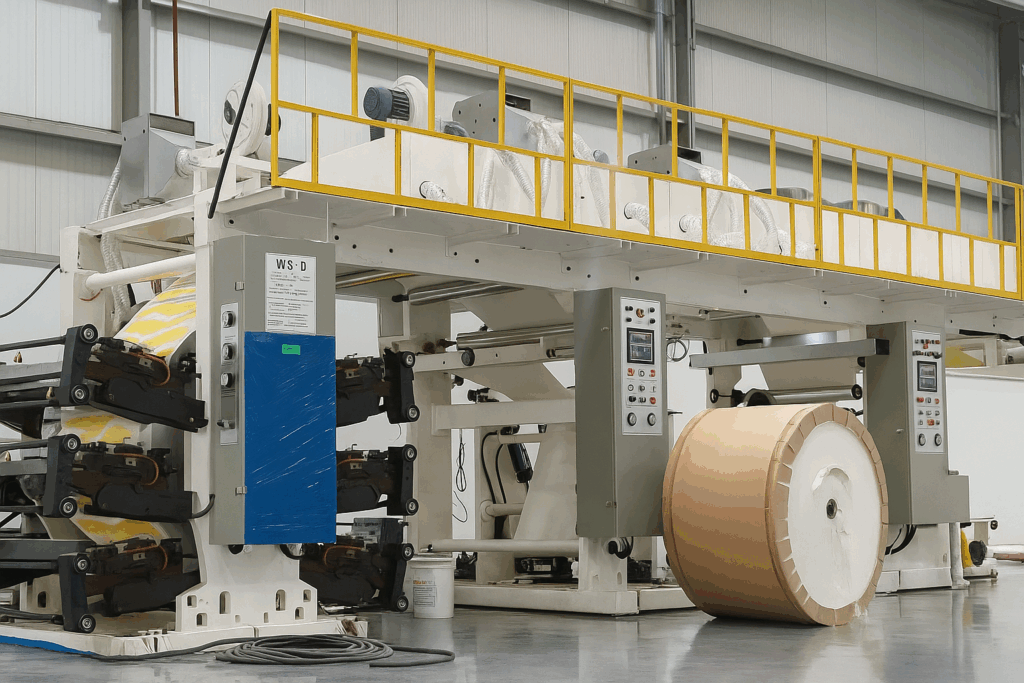

C.I. Fleox printing Machine

Feature of C.I Type flexo printing machine

The Most Advanced and Reliable Solution for High-Quality Paper Cup Printing

Among various types of flexographic printing machines, the CI (Central Impression) type stands out for its large size, high cost, and unmatched color precision. It is the ideal choice for high-end, full-color printing, such as paper cups.

A key challenge in flexographic printing is ink smudging, especially when ink transfers to the inner surface of cups due to incomplete drying. This typically results from slow printing speeds or limited drying zones.

The CI type solves this with ample drying capacity and a robust machine design, preventing ink transfer issues. Unlike line or stack types, it features a central impression cylinder that maintains strong web tension and stable substrate control, ensuring perfect color registration, even in complex multi-color jobs.

Key Advantages of CI Type Flexo Printing Machine:

Superior color registration, even in complex multi-color jobs

Strong, consistent paper tension through a central impression drum

Large drying units to prevent ink smudging or inner-cup ink transfer

Ideal for high-quality paper cup production

.

Technical Specification – CI Type Flexo Printing Machine

Max. Printing Width: 1000 mm

Printing Method: Roll-to-roll (with Unwinder and Rewinder)

Max. Printing Speed: 110 meters per minute

Applicable Paper: 120 gsm to 400 gsm

Printing Colors:

4 Colors

4 Colors + 1 Varnish

6 Colors

6 Colors + 1 Varnish

Paper Tension Control:

Automatic Paper Tension Controller

Equipped with EPC (Electronic Paper Control) for precise web alignment and smooth rewinding

Surface Treatment:

Corona Treatment System for improved varnish and coating adhesion

Printing Type:

Central Drum (CI – Central Impression Type)

Your Go-To Videos

Video For Machine Operation

Video Playlist