About Us

Established in 1979, our company is proud to be the first in Korea to develop and manufacture paper cup forming machines.

With over four decades of expertise, we have become Korea’s leading manufacturer and supplier of paper cup production equipment.

We are widely recognized for offering the most comprehensive range of paper cup machinery in the domestic market, supported by cutting-edge facilities and continuous innovation.

Not only do we dominate the Korean market, but we are also the No.1 exporter of paper cup equipment from Korea, supplying our machines to clients all around the world. Our commitment to quality, reliability, and customer satisfaction has made us a trusted global partner in the paper cup industry.

Our Manufacturing activity

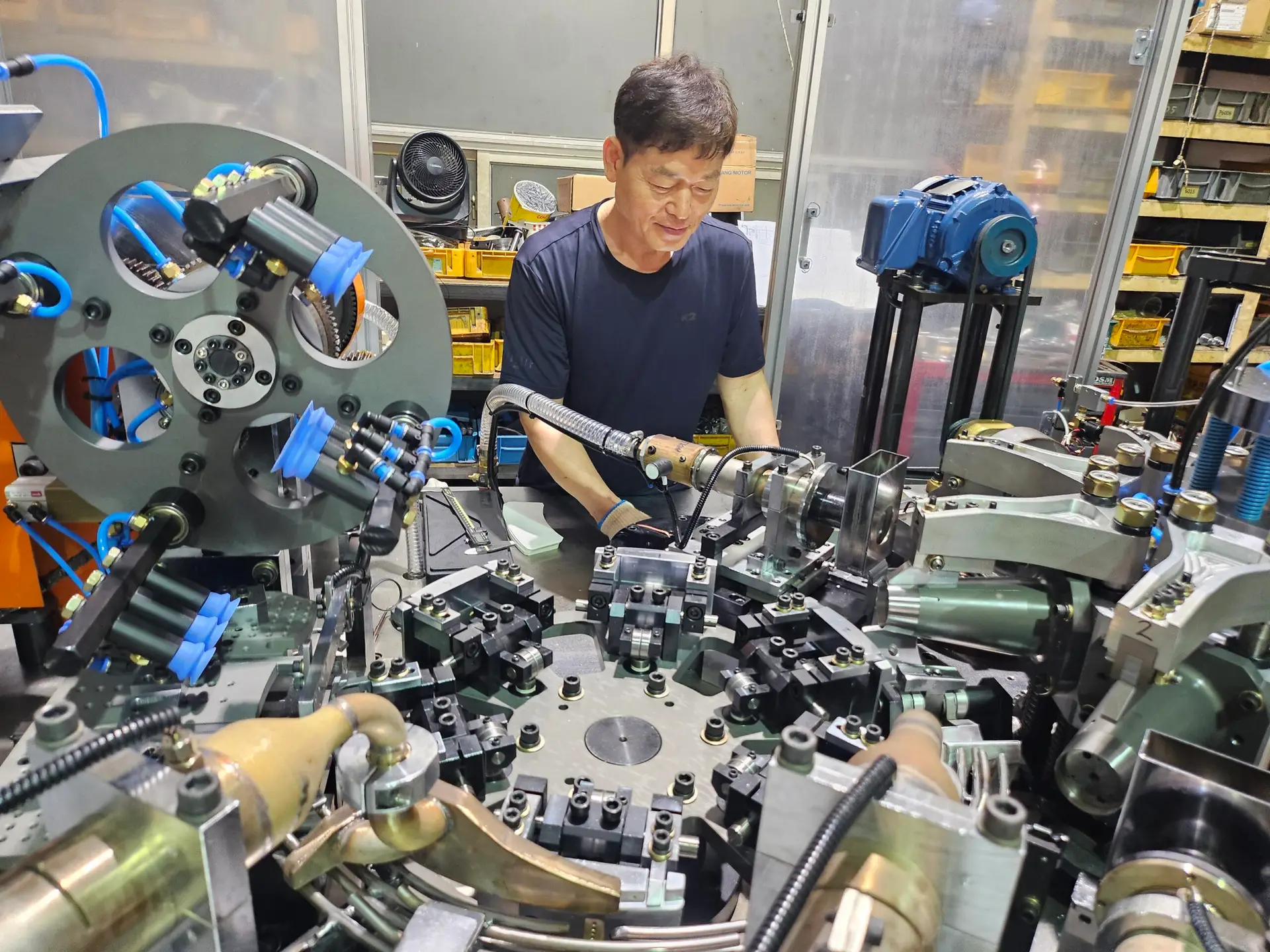

manufacturing SUPER SH-K01

Each of our machines is crafted with utmost care by our highly experienced technicians, who handle every single part from machining to assembly — with precision and dedication. Even the smallest component is treated as critically important, like the heart of the machine, ensuring exceptional quality and reliability in every unit we produce.

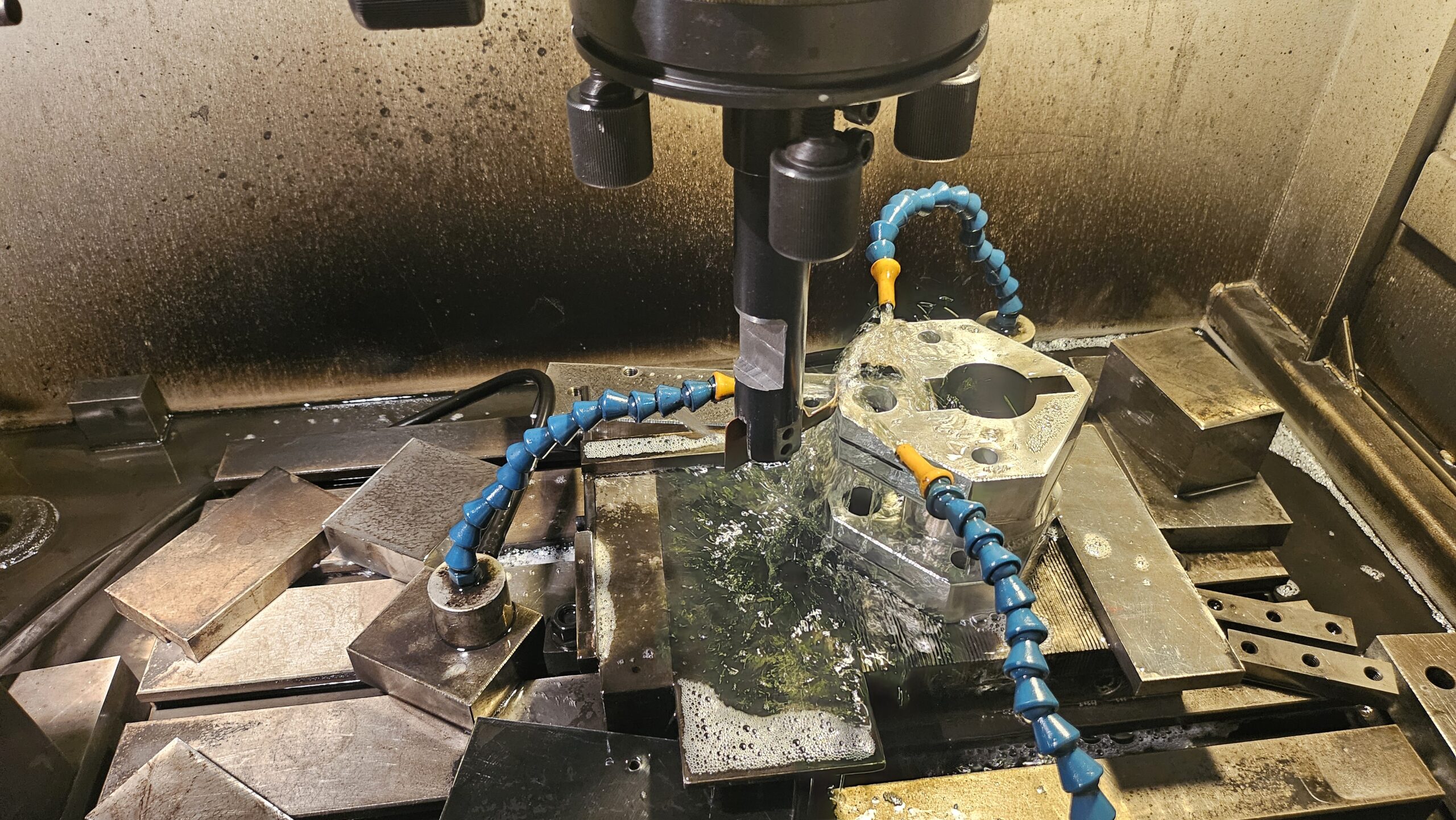

cNC Machine tool

CNC machining for high-precision cutting and processing beyond the capability of manual work.

Manufacturing C. I Type flexo printing machine

Due to the large size of the machines, they are manufactured in our company’s dedicated annex building. This specialized facility allows us to handle the assembly and testing of large-scale equipment

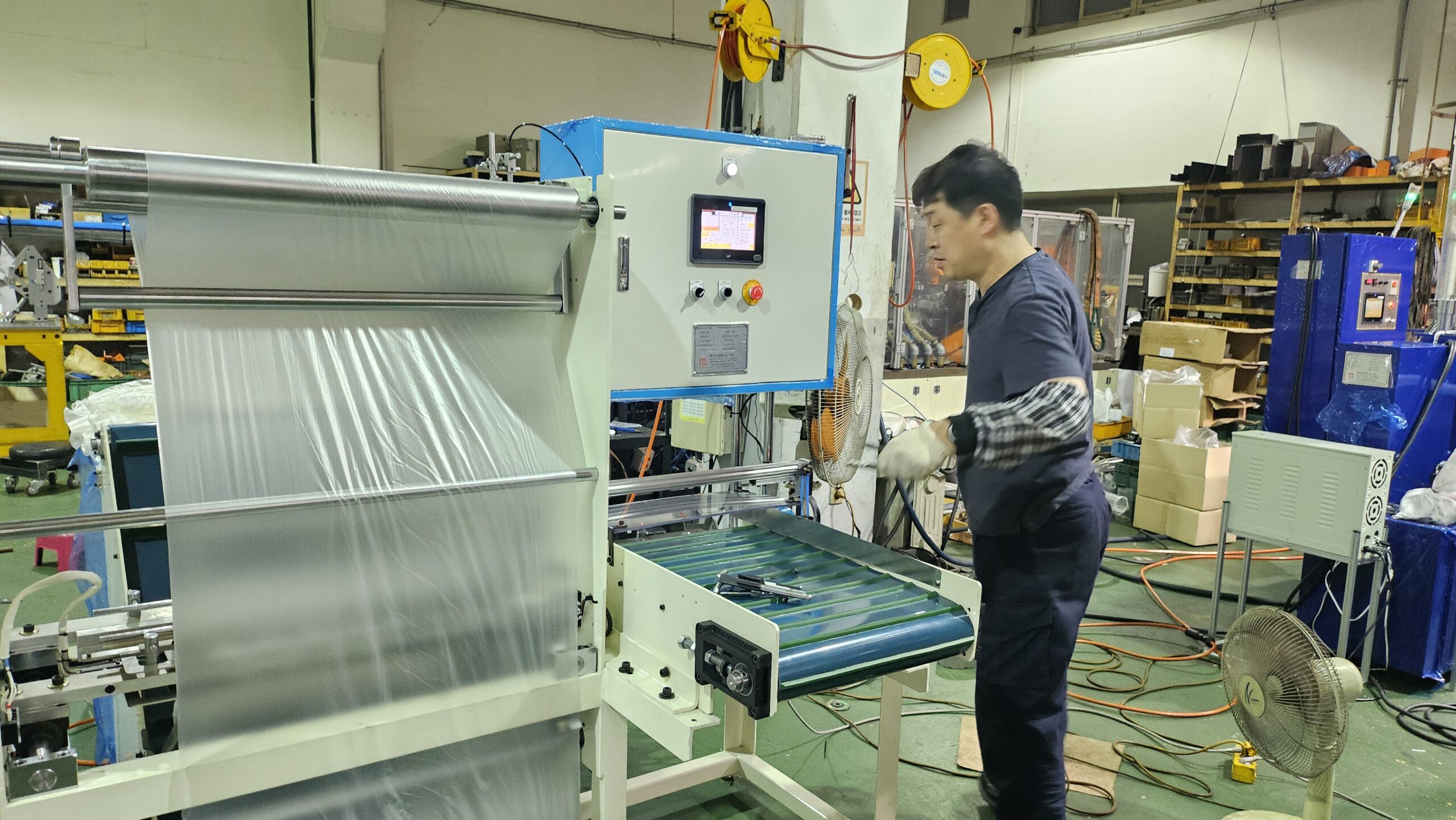

Manufacturing Packing Machine

A short description of the service and how the visitor will benefit from it.

Functional testing WSGP1700 and 3sets of flat rim forming macine in line

Automation system for ice cream paper cups designed to create a flat rim for aluminum foil sealing.

Manufacturing WSGP-1700

Our dedicated team of technicians, with a combined 30 years of experience, craft each product with precision and care.

Manufacturing Machines for Calippo-style Ice Cream Containers

These machines are engineered for forming tubular, push-up type containers commonly used in frozen treat packaging, ensuring high precision, hygiene, and productivity.

maufacturing Paper Punching Machine.

A high-speed punching system engineered to support multiple paper cup forming units per single machine, ensuring maximum efficiency and throughput.

Manufacturing SH-K100B

A fully integrated system that performs printing and punching in a single process, improving efficiency and alignment accuracy.

Manufacturing mH-K01

MH-K01 130 paper cups per minute and are engineered to sustain flawless performance, unchanged from new condition, even after decades of continuous operation.

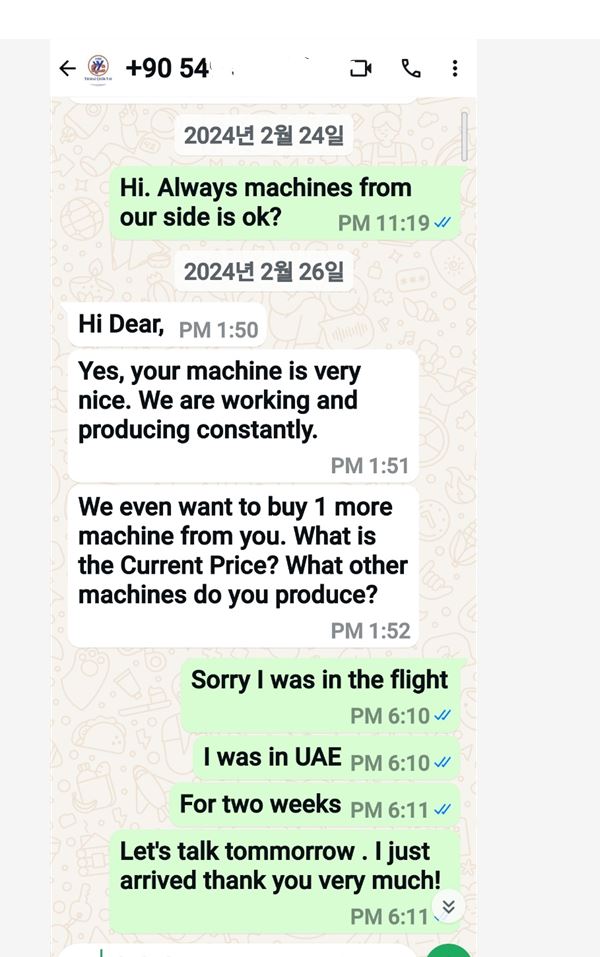

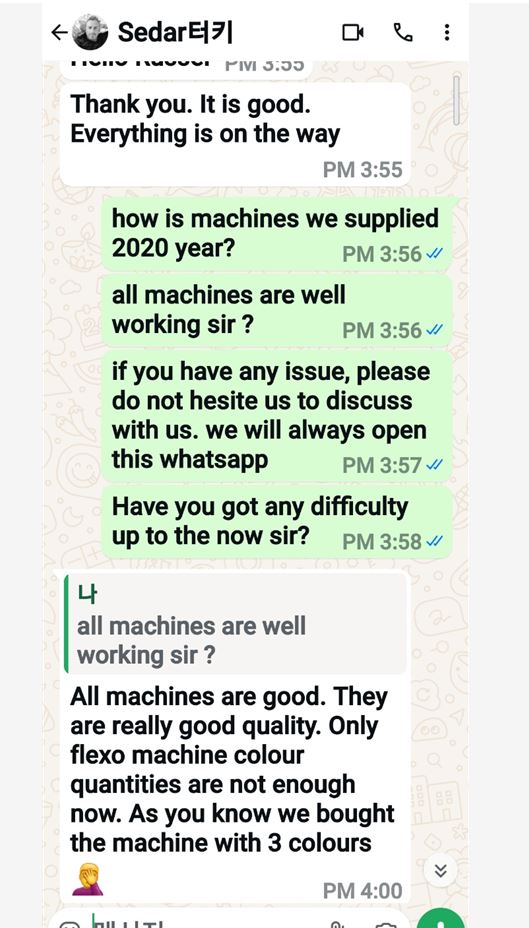

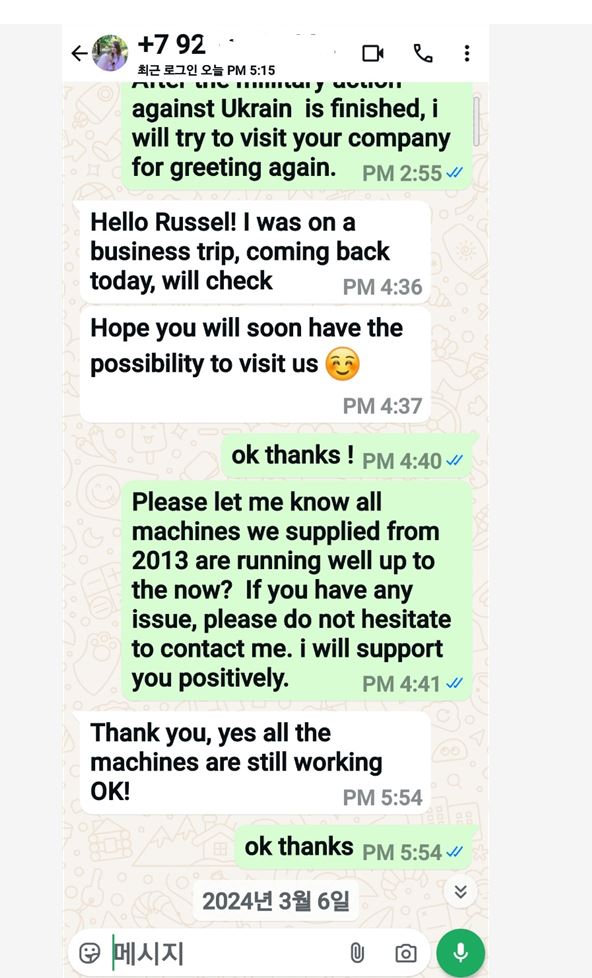

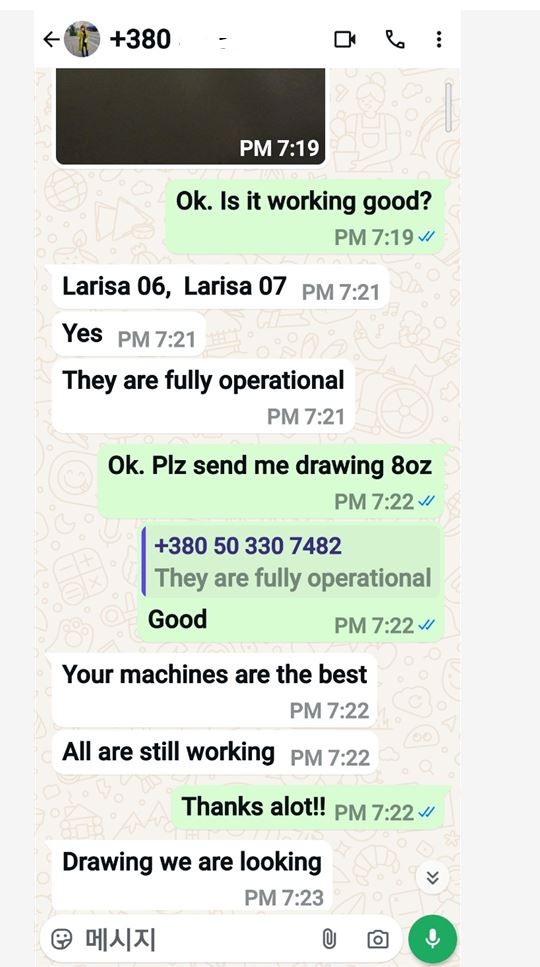

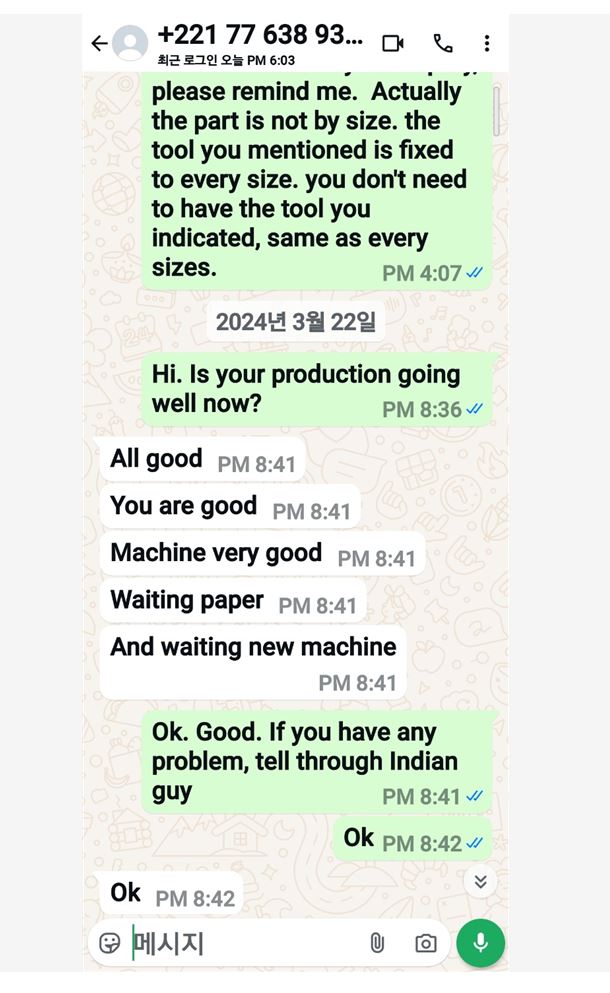

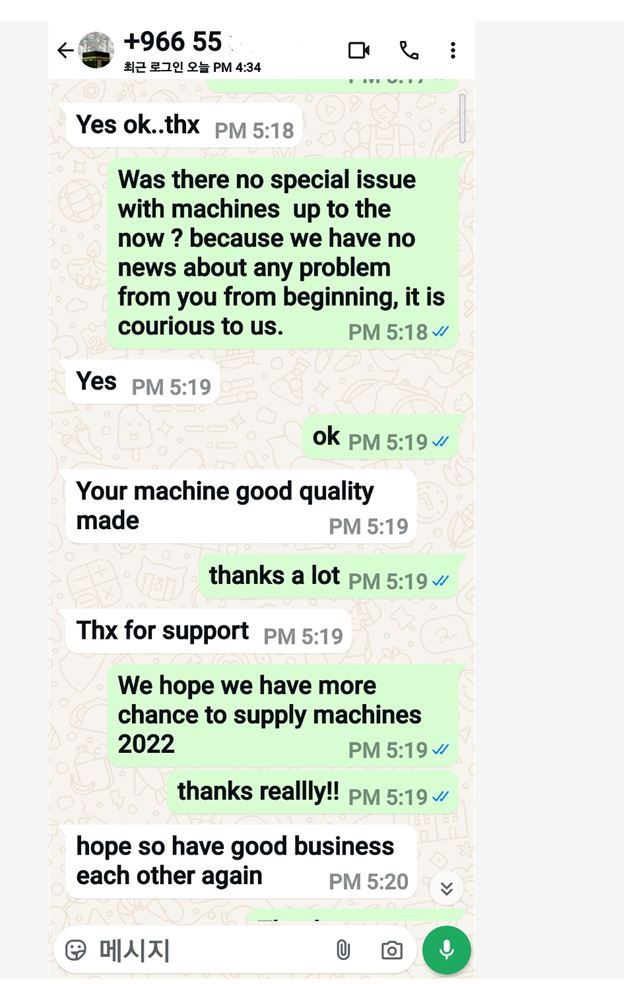

Client Testimonials

We always do our best in the customer’s favor.

Please feel free to contact Mr. Russel Kim for any questions or assistance regarding paper cup manufacturing.