Medium-Speed Paper Cup Forming Machine – SH-K01 & SH-K02

SH-K01

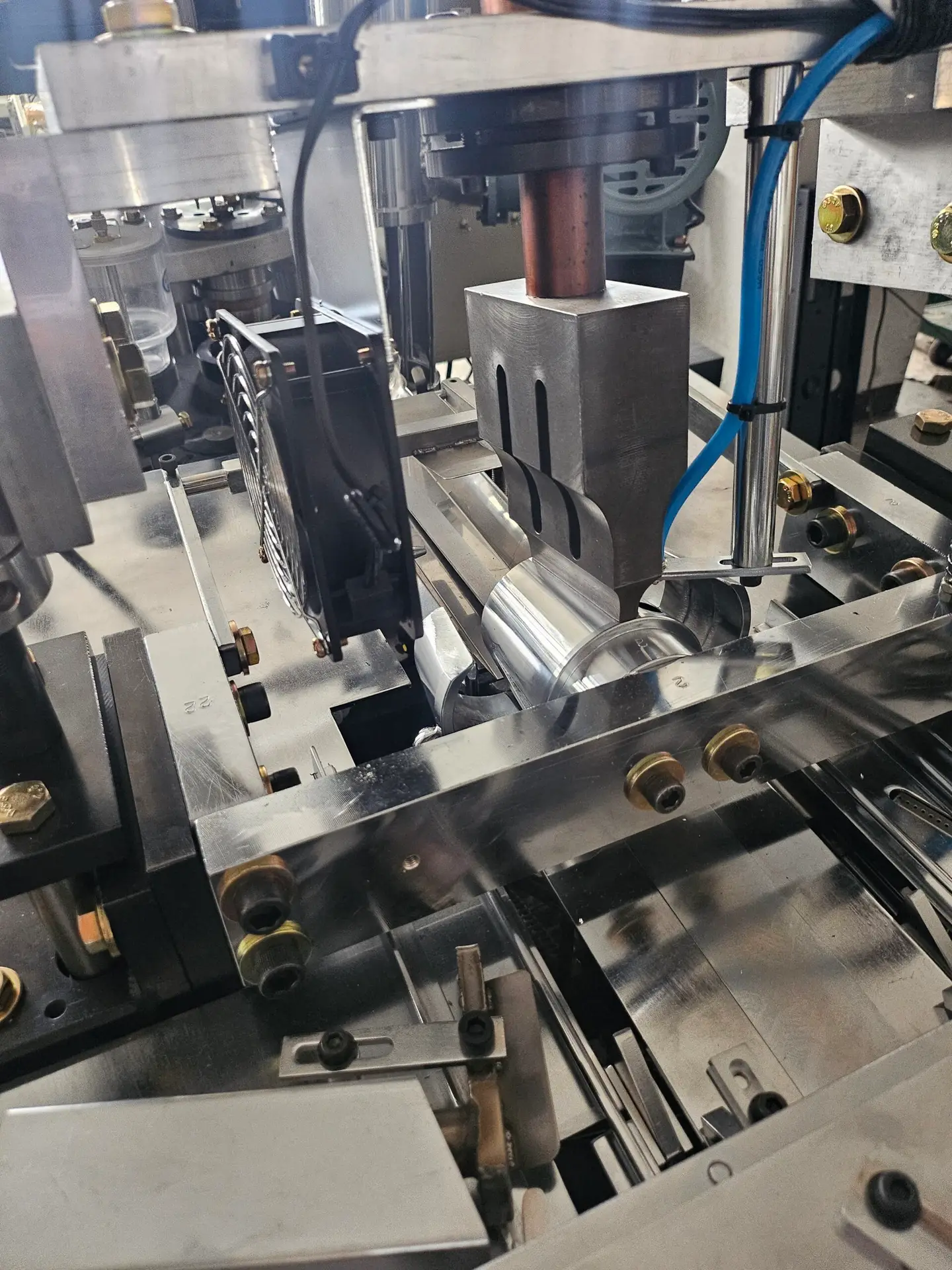

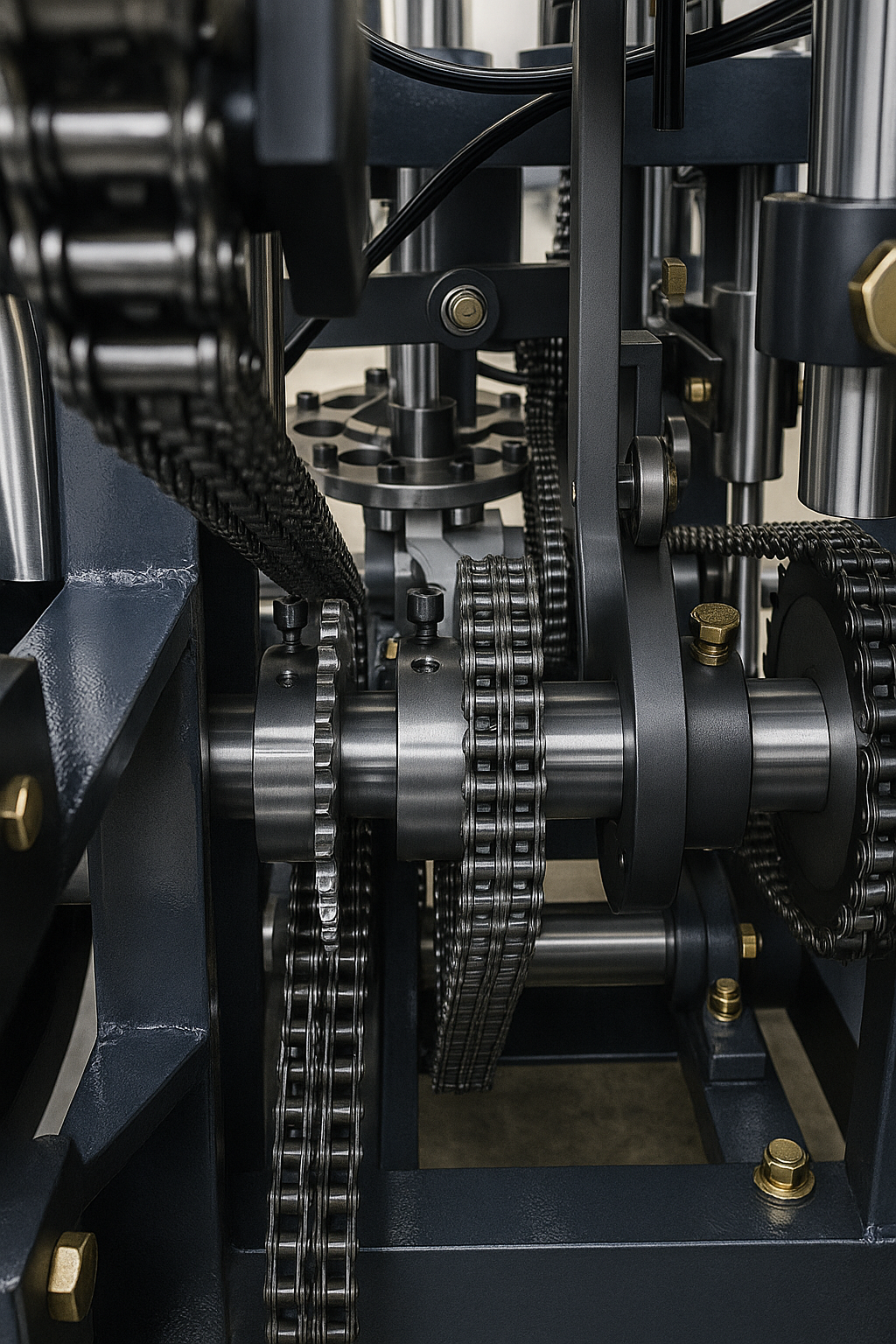

Super durable ultrasonic sealer

Superior Ultrasonic Sealing System

A common issue with conventional ultrasonic sealers is that they are easily damaged by overloads caused by paper jams or heavy pressure. This is primarily because most of their key components are made from aluminum or aluminum alloys, which lack durability under high stress.

However, our machines are engineered differently. We do not use aluminum parts in our ultrasonic sealing units. Instead, we apply specially designed, high-strength metal components that are exceptionally resistant to overload pressure. These components not only ensure durability and longer lifespan, but also transfer ultrasonic waves to the paper with high efficiency, ensuring consistent and strong sealing performance.

SH-K01

Key Features

· Simple Construction

Designed for easy maintenance and smooth operation

· No Skilled Technicians Required

Can be operated by anyone after basic training provided by the manufacturer

· No Air Compressor Needed

Lower operational costs and simplified installation

· Beginner-Friendly

Ideal for operators with no prior experience

Specifications

· Side Sealing

· Preheating: Hot air

· Main Sealing: Ultrasonic system (Double-stage sealing)

· Bottom Sealing

· Sealed by hot air

· Compatible Paper Coatings

· PLA

· PBS

· PE (single & double-sided)

· Water-based PE

· Compatible Paper Types

· Single-side and double-side coated paper

· Production Speed

· 75–80 cups/min (based on 7oz cups)

· Up to 70 cups/min (based on 12oz cups)

· Speed control via inverter

· Electric Power Requirement

Start-up power: 20 kW

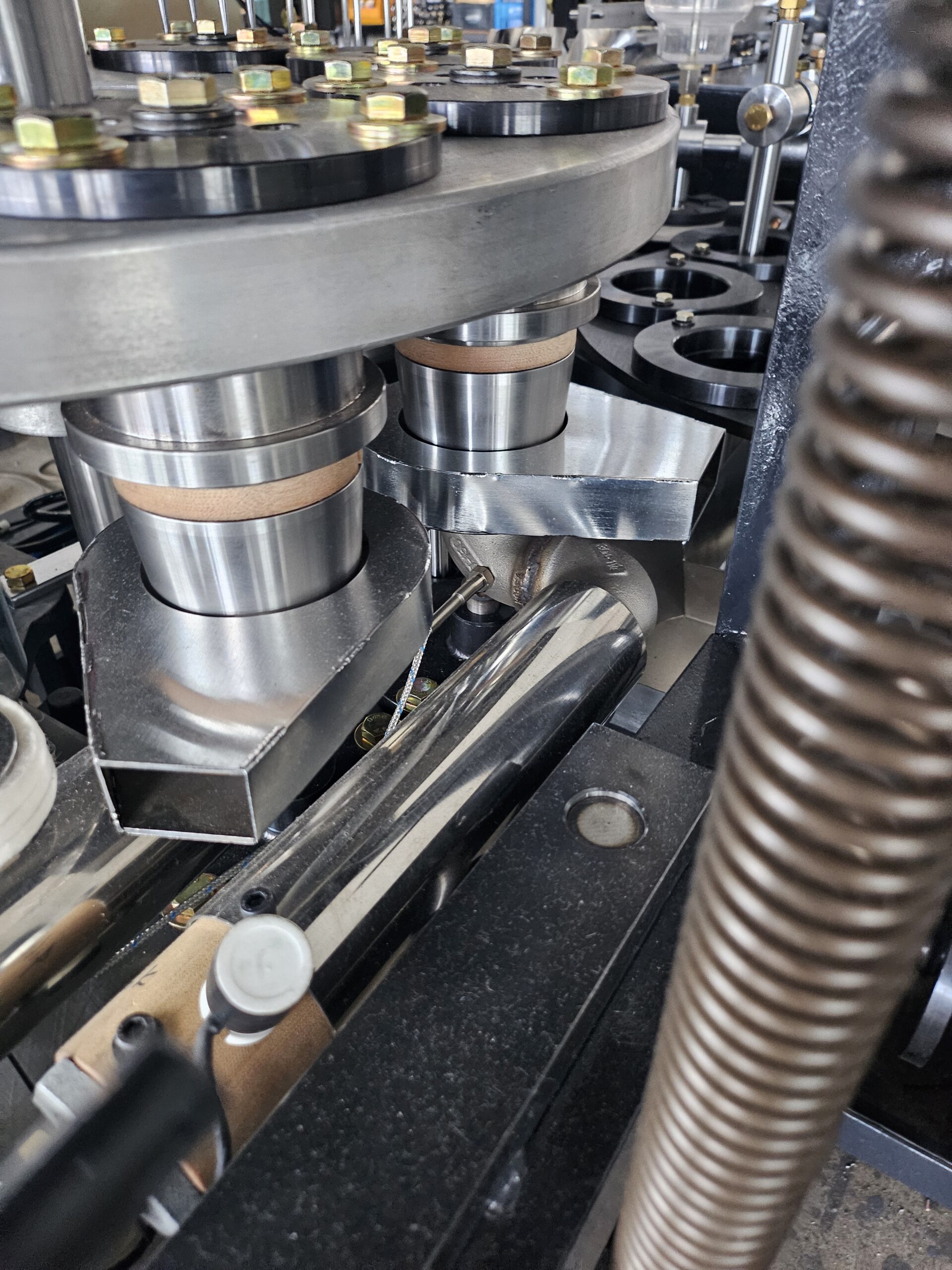

Side sealing method

Hot air for preheating Ultrasonic for main sealing

Bottom sealing method

By Hot Air

Structure simple

Designed for easy maintenance, with simple replacement of spare parts and straightforward adjustments.

Video For SH-K01 operation

Video Collection

SH-K02

Key Features

Simple Construction

Designed for easy maintenance and smooth operationNo Skilled Technicians Required

Can be operated by anyone after basic training provided by the manufacturerNo Air Compressor Needed

Lower operational costs and simplified installationBeginner-Friendly

Ideal for operators with no prior experience

Specifications

Side Sealing

Preheating: Hot air

Main Sealing: Metal heater(Double-stage sealing)

Bottom Sealing

Sealed by Metal Coil heater

Compatible Paper Coatings

Only PE

Compatible Paper Types

Only single-side coated paper

Production Speed

75–80 cups/min (based on 7oz cups)

Speed control via inverter

Electric Power Requirement

Start-up power: 8 kW

Video For SH-K02 operation

Video Collection

SH-K01D FOR DOUBLE WALL

SH-K02H Handle Type Paper Cup Forming Machine

Key Features

Simple Construction

Designed for easy maintenance and smooth operationNo Skilled Technicians Required

Can be operated by anyone after basic training provided by the manufacturerNo Air Compressor Needed

Simplified installation and reduced operational costBeginner-Friendly

Ideal for operators with no prior experienceProven Market Performance in the Middle East

SH-K02H has gained strong demand across the Middle East, including Saudi Arabia, UAE, Oman, Bahrain, Egypt, and more.

In particular, over 90% of paper cup manufacturers in Saudi Arabia are using SH-K02H for their production.

Specifications

Side Sealing

Preheating: Hot air

Main Sealing: Metal heater (Double-stage sealing)

Bottom Sealing

Sealed by metal coil heater

Handle Sealing

Fixed by cartridge metal heater

Compatible Paper Coatings

PE only

Compatible Paper Types

Single-side coated paper only

Production Speed

75–80 cups/min (based on 7oz cups)

Speed control via inverter

Electric Power Requirement

Start-up power: 8 kW

Video For SH-K02 H operation

Video Collection

SH-K01D FOR DOUBLE WALL

SH-K01D – Outer Sleeve Forming Machine

Key Features

Simple Construction

Designed for easy maintenance and smooth operationNo Skilled Technicians Required

Can be operated by anyone after basic training provided by the manufacturerNo Air Compressor Needed

Simplified installation and reduced operational costBeginner-Friendly

Ideal for operators with no prior experience

Specifications

Side Sealing

Performed using hot melt adhesive

Inner Cup Adhesion

Cold glue applied for bonding the inner cup to the outer sleeve

Compatible Paper Types

Non-coated cardboard paper

Production Speed

Up to 60 cups/min

Speed Control

Controlled via inverter

Electric Power Requirement

Start-up power: 12 kW

Video For SH-K01D operation

Video Collection