Unchanging quality and reliability

— built to last for 100 years.

For customers who find it burdensome to invest in a high-end machine like the SUPER SH-K01, we proudly recommend the MH-K01 — a practical and cost-effective solution. This model offers a stable production speed of 130-140cups per minute, and has earned high satisfaction from users who value consistent performance without stretching their budget.

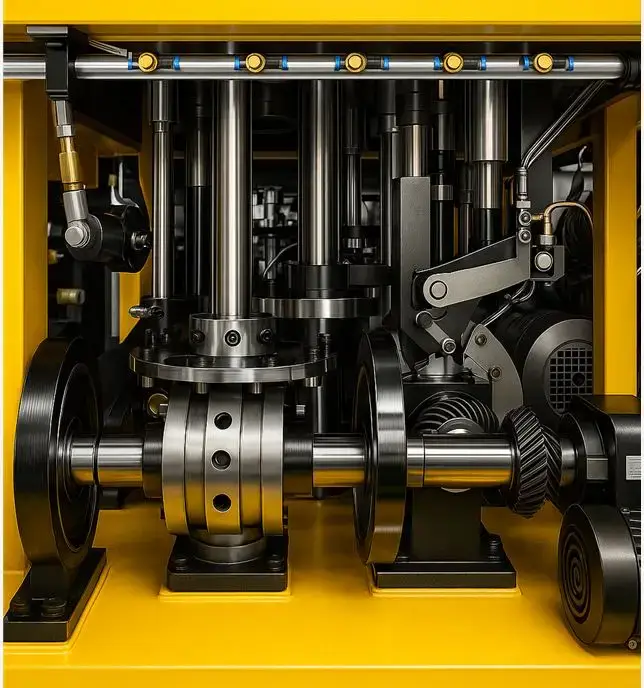

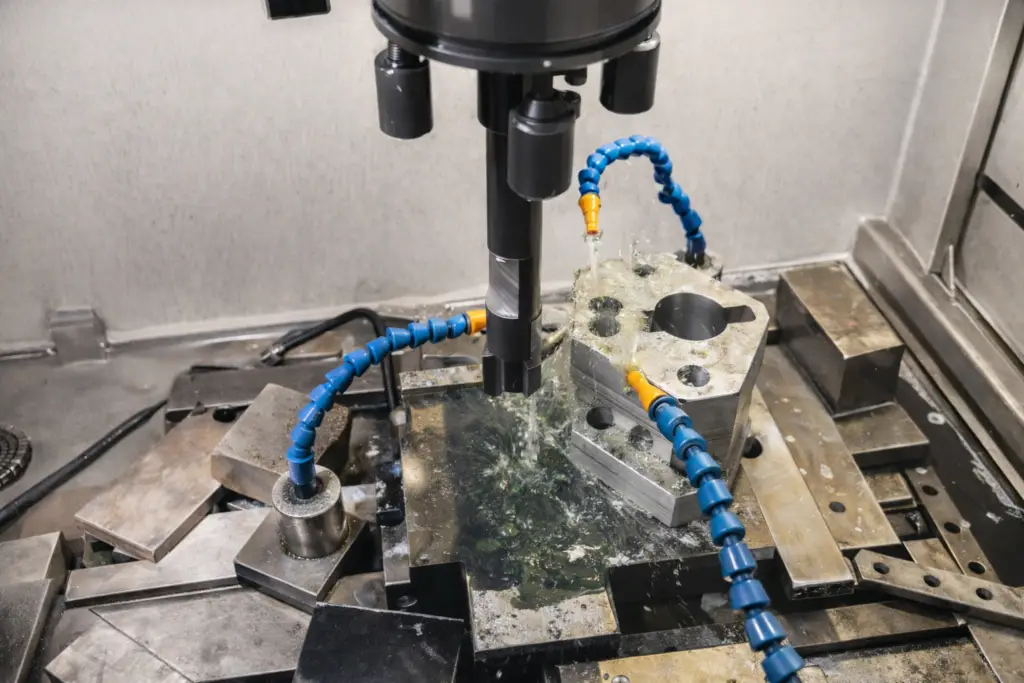

The MH-K01 is not just an affordable alternative — it is a product of our 40 years of expertise in paper cup forming machine manufacturing and precision engineering. Departing from conventional production methods, this model is hand-assembled with care and craftsmanship by our skilled technicians who have long been part of our team.

To achieve exceptional durability and reliability, we have significantly reduced — or even eliminated — mechanical vibrations, which are one of the most damaging factors affecting machine performance. As a result, customers using the MH-K01 can rest assured that machine-related concerns will be minimized, allowing them to focus more on production and less on maintenance.